Advantages of aluminum formwork compared with traditional formwork

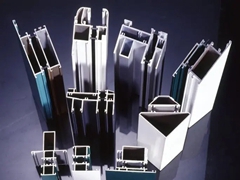

In the current building formwork, the more popular formwork is aluminum formwork, because the service life of aluminum formwork is very long, not to mention that it can be recycled, which is more conducive to our engineering construction in terms of work efficiency, so the application of aluminum formwork is more and more. more extensive. What are the advantages of aluminum formwork compared with traditional formwork? After reading this article, you will know!

1. The aluminum formwork is in the standard layer, which can highlight the advantages, because a set of formwork (standard board plus special-shaped board) can be constructed without modification. In the non-standard layer (generally the bottom layer is the bottom layer and the second layer is the non-standard layer), wooden formwork needs to be used to save capital costs.

2. In order to improve the efficiency of the aluminum formwork to a greater extent, it is recommended that the contractor prepare the materials to be prepared before construction, and do not wait until the construction to find them. For example, the release agent should be purchased in advance. Otherwise, it will be very busy during construction. It is recommended that aluminum formwork can be used for vague construction when the price of traditional formwork and aluminum formwork is not much different, and the requirements for multiple construction periods are strict.

3. The aluminum formwork is processed in the factory with equipment, which can ensure the flatness and quality of the joint. Each piece is connected by a pin connection hole. As long as the pin is fixed, it can be seamlessly connected, and concrete leakage will not be caused by excessive joints. , resulting in honeycomb and pitted concrete surface. From these two aspects, the appearance and quality of concrete poured by aluminum alloy formwork technology can be guaranteed.

4. The average operating cost is low. Although aluminum formwork has a higher purchase price per square meter, when it is used in buildings with more than 30 floors or reused for recycling, we can see that its average application cost is very advantageous compared to other formwork skills.

5. The aluminum formwork has a short construction period, and the aluminum alloy formwork technique is to use the "quick release system". The so-called "quick dismantling system" is to ensure that the construction of a certain layer of concrete reaches a certain strength. Under the premise of safety, in addition to removing the support head of the retaining rod in advance, take out the corrugated bone, template, etc. at the same time, and transport it from the material transfer port to the upper layer. The retained vertical rod must be a stable body.

1. The aluminum formwork is in the standard layer, which can highlight the advantages, because a set of formwork (standard board plus special-shaped board) can be constructed without modification. In the non-standard layer (generally the bottom layer is the bottom layer and the second layer is the non-standard layer), wooden formwork needs to be used to save capital costs.

2. In order to improve the efficiency of the aluminum formwork to a greater extent, it is recommended that the contractor prepare the materials to be prepared before construction, and do not wait until the construction to find them. For example, the release agent should be purchased in advance. Otherwise, it will be very busy during construction. It is recommended that aluminum formwork can be used for vague construction when the price of traditional formwork and aluminum formwork is not much different, and the requirements for multiple construction periods are strict.

3. The aluminum formwork is processed in the factory with equipment, which can ensure the flatness and quality of the joint. Each piece is connected by a pin connection hole. As long as the pin is fixed, it can be seamlessly connected, and concrete leakage will not be caused by excessive joints. , resulting in honeycomb and pitted concrete surface. From these two aspects, the appearance and quality of concrete poured by aluminum alloy formwork technology can be guaranteed.

4. The average operating cost is low. Although aluminum formwork has a higher purchase price per square meter, when it is used in buildings with more than 30 floors or reused for recycling, we can see that its average application cost is very advantageous compared to other formwork skills.

5. The aluminum formwork has a short construction period, and the aluminum alloy formwork technique is to use the "quick release system". The so-called "quick dismantling system" is to ensure that the construction of a certain layer of concrete reaches a certain strength. Under the premise of safety, in addition to removing the support head of the retaining rod in advance, take out the corrugated bone, template, etc. at the same time, and transport it from the material transfer port to the upper layer. The retained vertical rod must be a stable body.

Leave a comment