You need to know when purchasing and using aluminum alloy building profile products

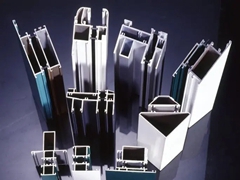

Aluminum alloy building profiles have become important materials for home decoration due to their high strength, light weight, corrosion resistance, good decoration, long service life and rich colors. At present, the types of aluminum alloy building profiles sold on the market are mainly divided into: anodized colored profiles, electrophoretic painted profiles, powder sprayed profiles, fluorocarbon paint sprayed profiles, and thermal insulation profiles. Consumers should pay attention to the following six points when purchasing and using aluminum alloy building profile products:

Aluminum alloy building profiles

1. Ask the seller for the quality inspection report of the batch of products.

2. Check the product factory certificate, pay attention to the factory date, specifications, technical conditions, company name and production license number.

3. Carefully observe the surface condition of the product, the product should be bright in color, good in luster, and there should be no obvious scratches, bubbles and other defects on the surface.

4. Be sure to pay attention to the wall thickness of the product. The product thickness of doors and window materials should not be less than 1.2mm.

5. Pay attention to the thickness of the surface coating of the product. The film thickness of anodized products is not less than 10μm, the film thickness of electrophoretic paint products is not less than 17μm, the thickness of powder spray coating is not more than 40-120μm, and fluorocarbon paint is sprayed. The product should be above the second coating, not less than 30μm.

6. For users in coastal areas, it is best to choose electrophoretic paint profiles, powder spray profiles or fluorocarbon spray profiles with better corrosion resistance.

Aluminum alloy building profiles

1. Ask the seller for the quality inspection report of the batch of products.

2. Check the product factory certificate, pay attention to the factory date, specifications, technical conditions, company name and production license number.

3. Carefully observe the surface condition of the product, the product should be bright in color, good in luster, and there should be no obvious scratches, bubbles and other defects on the surface.

4. Be sure to pay attention to the wall thickness of the product. The product thickness of doors and window materials should not be less than 1.2mm.

5. Pay attention to the thickness of the surface coating of the product. The film thickness of anodized products is not less than 10μm, the film thickness of electrophoretic paint products is not less than 17μm, the thickness of powder spray coating is not more than 40-120μm, and fluorocarbon paint is sprayed. The product should be above the second coating, not less than 30μm.

6. For users in coastal areas, it is best to choose electrophoretic paint profiles, powder spray profiles or fluorocarbon spray profiles with better corrosion resistance.

Leave a comment