The causes of uneven oxidation and coloring of industrial aluminum profiles

The uneven oxidation and coloring of industrial aluminum profiles will affect the appearance of the finished product to a certain extent. The uneven dyeing phenomenon is more serious and even increases the defective rate. However, the cause of oxidative dyeing of aluminum profiles is often attributed to abnormal dyeing, but ignoring the oxidation process can also lead to uneven dyeing of industrial aluminum profiles.

1. The principle of oxidation and coloring of industrial aluminum profiles

The anodized film of industrial aluminum profiles or aluminum products is composed of a large number of hexagonal crystals perpendicular to the metal surface. There is a membrane hole in the center of each crystal, which has a strong adsorption force. When the alumina product is immersed in the dye solution, the dye molecules diffuse into the film pores of the oxide film and form covalent and ionic bonds with the oxide film that are difficult to separate. This bonding is reversible, and desorption will occur under certain conditions. Therefore, after dyeing, the dye must be sealed and fixed in the film pores to improve the corrosion resistance and abrasion resistance of the oxide film.

2. The effect of anodizing on dyeing

In the entire oxidation coloring process of industrial aluminum profiles, the poor dyeing caused by the oxidation process is more common. The thickness of the oxide film and the uniform pores are the premise and basis for obtaining uniform color in the dyeing process. In order to obtain a uniform oxide film, it is very important to ensure adequate circulation, cooling and good electrical conductivity in addition to the stability of the oxidation process.

The concentration of sulfuric acid is controlled at 180-200g/L. A slightly higher concentration of sulfuric acid can accelerate the dissolution reaction of the oxide film, which is conducive to the expansion of pores and makes it easier to dye;

A process of oxidative coloring of industrial aluminum profiles is the basis of dyeing. Before dyeing, it was difficult or impossible to see anodizing issues. Once dyed, we can clearly see the color unevenness. At this point, manufacturers often attribute the problem to abnormal dyeing and neglect to look for the cause during the oxidation process.

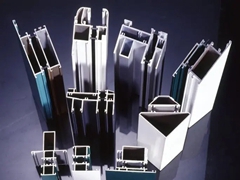

Skills and methods to distinguish the quality of industrial aluminum profiles:

1. The wall thickness of aluminum profiles is related to meter weight, price and bearing capacity.

2. Surface coating thickness of aluminum profile products. During surface treatment of industrial aluminum profiles, the film thickness of the electrophoretic coating should be at least 17μm. The film thickness of anodized products should not be less than 10μm. The coating thickness of powder spraying should not exceed 40-120μm. Fluorocarbon paint spray products should not be less than 30μm

3. The surface of industrial aluminum profiles should be smooth, bright, bright in color, smooth, free of bubbles, obvious scratches and other defects.

4. Cleaning tools: There are stains on the surface of daily industrial aluminum profiles. The proper cleaning method is to use a soft tool, such as a rag or cotton gauze surface, rather than a hard object, such as a brush.

5. Procurement in coastal areas, the rainy season in coastal areas is long, and it is necessary to choose a corrosion-resistant surface treatment method with better surface treatment, such as electrophoretic coating profiles.

6. In other respects, the soft power and hard power of the manufacturer are better by a lot of comparisons. A good manufacturer is usually a guarantee of quality.

1. The principle of oxidation and coloring of industrial aluminum profiles

The anodized film of industrial aluminum profiles or aluminum products is composed of a large number of hexagonal crystals perpendicular to the metal surface. There is a membrane hole in the center of each crystal, which has a strong adsorption force. When the alumina product is immersed in the dye solution, the dye molecules diffuse into the film pores of the oxide film and form covalent and ionic bonds with the oxide film that are difficult to separate. This bonding is reversible, and desorption will occur under certain conditions. Therefore, after dyeing, the dye must be sealed and fixed in the film pores to improve the corrosion resistance and abrasion resistance of the oxide film.

2. The effect of anodizing on dyeing

In the entire oxidation coloring process of industrial aluminum profiles, the poor dyeing caused by the oxidation process is more common. The thickness of the oxide film and the uniform pores are the premise and basis for obtaining uniform color in the dyeing process. In order to obtain a uniform oxide film, it is very important to ensure adequate circulation, cooling and good electrical conductivity in addition to the stability of the oxidation process.

The concentration of sulfuric acid is controlled at 180-200g/L. A slightly higher concentration of sulfuric acid can accelerate the dissolution reaction of the oxide film, which is conducive to the expansion of pores and makes it easier to dye;

A process of oxidative coloring of industrial aluminum profiles is the basis of dyeing. Before dyeing, it was difficult or impossible to see anodizing issues. Once dyed, we can clearly see the color unevenness. At this point, manufacturers often attribute the problem to abnormal dyeing and neglect to look for the cause during the oxidation process.

Skills and methods to distinguish the quality of industrial aluminum profiles:

1. The wall thickness of aluminum profiles is related to meter weight, price and bearing capacity.

2. Surface coating thickness of aluminum profile products. During surface treatment of industrial aluminum profiles, the film thickness of the electrophoretic coating should be at least 17μm. The film thickness of anodized products should not be less than 10μm. The coating thickness of powder spraying should not exceed 40-120μm. Fluorocarbon paint spray products should not be less than 30μm

3. The surface of industrial aluminum profiles should be smooth, bright, bright in color, smooth, free of bubbles, obvious scratches and other defects.

4. Cleaning tools: There are stains on the surface of daily industrial aluminum profiles. The proper cleaning method is to use a soft tool, such as a rag or cotton gauze surface, rather than a hard object, such as a brush.

5. Procurement in coastal areas, the rainy season in coastal areas is long, and it is necessary to choose a corrosion-resistant surface treatment method with better surface treatment, such as electrophoretic coating profiles.

6. In other respects, the soft power and hard power of the manufacturer are better by a lot of comparisons. A good manufacturer is usually a guarantee of quality.

Leave a comment