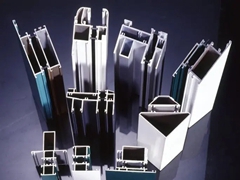

Details processing in the production of industrial aluminum profiles

When producing aluminum profiles, manufacturers need to pay attention to a lot of subtle processing, and the processing must be standardized, so as to ensure the beauty and quality of industrial aluminum profiles for subsequent use. Here are some details that need to be paid attention to in the production of industrial aluminum profiles for your reference:

1. Powder coating on the surface of industrial aluminum profiles

Before the actual spraying, you can try spraying a few times. Through the test spraying, the size of the powder and the distribution of the powder at both ends of the industrial aluminum profile can be observed, so as to find a suitable spraying method.

2. Selection of fixture location

The load-carrying capacity of the wire clips hanging at both ends of the industrial aluminum profile should exceed the quality of the industrial aluminum profile, and the contact area between the wire clip used in the middle part and the outer surface of the industrial aluminum profile should be minimized during manufacturing and use. Any damage to the outer surface of the fixture should be repaired by powder spraying in time, and the installation position of the fixture should follow the corresponding mechanical principles.

3. Pre-oxidation treatment

The only steps here are degreasing and chroming to reduce raw material consumption, improve production efficiency, and reduce energy consumption in the drying process of industrial aluminum profiles. Larger racks can be selected, so that as many industrial aluminum profiles to be processed can be loaded as possible.

4. Treatment of moisture

After all, it is dried together, there will be special circumstances, and there may still be water residue. In order to avoid damaging the coating on the surface of the industrial aluminum profile, and at the same time, the industrial aluminum profile is easily deformed when the temperature is too high, so it cannot be baked in the furnace. Air drying or blowing with an air gun can be used.

These are the details that industrial aluminum profile manufacturers need to do in the profile production process. If these are handled properly, the service life of industrial aluminum profiles can be extended to a certain extent.

1. Powder coating on the surface of industrial aluminum profiles

Before the actual spraying, you can try spraying a few times. Through the test spraying, the size of the powder and the distribution of the powder at both ends of the industrial aluminum profile can be observed, so as to find a suitable spraying method.

2. Selection of fixture location

The load-carrying capacity of the wire clips hanging at both ends of the industrial aluminum profile should exceed the quality of the industrial aluminum profile, and the contact area between the wire clip used in the middle part and the outer surface of the industrial aluminum profile should be minimized during manufacturing and use. Any damage to the outer surface of the fixture should be repaired by powder spraying in time, and the installation position of the fixture should follow the corresponding mechanical principles.

3. Pre-oxidation treatment

The only steps here are degreasing and chroming to reduce raw material consumption, improve production efficiency, and reduce energy consumption in the drying process of industrial aluminum profiles. Larger racks can be selected, so that as many industrial aluminum profiles to be processed can be loaded as possible.

4. Treatment of moisture

After all, it is dried together, there will be special circumstances, and there may still be water residue. In order to avoid damaging the coating on the surface of the industrial aluminum profile, and at the same time, the industrial aluminum profile is easily deformed when the temperature is too high, so it cannot be baked in the furnace. Air drying or blowing with an air gun can be used.

These are the details that industrial aluminum profile manufacturers need to do in the profile production process. If these are handled properly, the service life of industrial aluminum profiles can be extended to a certain extent.

Leave a comment