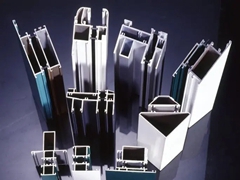

Application of industrial aluminum profiles in different industries

With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.With the modernization of science and technology and the development of artificial intelligence, the application scope of industrial aluminum profiles is becoming more and more extensive, such as automobile manufacturing, rail transit, electronics, robots, etc., which penetrate into almost all industries. Let's find out together.

1. In the automobile production workshop, we will see a lot of industrial aluminum profile fences or protective covers. These fences and shields are made of industrial aluminium profiles to demarcate safe areas. Fences are usually divided into mesh fences and plexiglass panels. The protective cover is made of various materials, including aluminum plate, wood, stainless steel or plexiglass plate, etc., depending on different requirements. Robotic operations are required in welding shops because welding is not only exposed to high temperatures and harsh light, but also to harmful substances such as dust. The welding robot can accurately weld, and a protective cover is added on the outside to prevent high-temperature metal particles from splashing into people's eyes or body and causing harm to people.

2. The robot has a certain range of activities during the operation. When assembling, it must be surrounded by industrial aluminum profile safety fence, and then install the safety gate to facilitate the operator to enter and exit. Because there are many people passing by the welding workshop. During the operation, the robot moves back and forth while working. If the safety area is not divided for protection, the robot arm may accidentally bump into people when it rotates, resulting in personal safety of the people, and at the same time, it can also prevent the collision and wear of the robot from external forces.

3. Electronic instruments are usually very precise, and the workshop should be waterproof and dustproof, because electronic products will change when exposed to water, affecting the performance of the products. Usually, there are robots working in electrical and electronic factories. Robots are not only more precise than humans for these complex electronic instruments, but they also don't make the product stick to sweat. The robot needs a dust-free space during operation, and the frame structure of this space is an industrial aluminum profile protective cover. The industrial aluminum profile protective cover is made of industrial aluminum profiles plus plexiglass or acrylic sheets, and is equipped with corresponding accessories such as bolts and nuts. Assembly is very simple and quick. Putting the robot inside to work can prevent products and equipment from being soiled by dust, and can also reduce the noise pollution generated when the machine is running.

The application cases of industrial aluminum profiles are not limited to the above, there are more. Different customers have different needs, and customize different types and uses of aluminum profile frames to meet different production needs.

Leave a comment