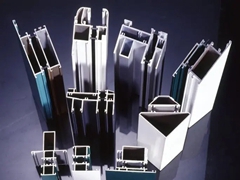

7 extrusion methods for aluminum profiles

Aluminum profile processing is a very important technology. There are many aspects that need to be considered when processing aluminum profiles. For users, the operation method should be considered the most in the process of processing, because the choice of different extrusion The effect of the aspect is different. The industrial aluminum profile manufacturer will tell you about the processing and extrusion method of aluminum profile.

Aluminum profile processing and extrusion

1. According to the extrusion direction: it can be divided into forward extrusion, reverse extrusion and lateral extrusion.

Second, according to the deformation characteristics: plane deformation extrusion, axisymmetric deformation extrusion, general three-dimensional deformation extrusion.

3. According to the lubrication state: non-lubricated extrusion, lubricated extrusion, glass lubrication extrusion, ideal lubrication extrusion (hydrostatic extrusion).

Fourth, according to the extrusion temperature: cold extrusion, warm extrusion, hot extrusion.

5. According to the type of mold or mold structure: flat die extrusion, cone die extrusion, split die extrusion, and perforated needle extrusion.

6. According to the shape or number of blanks: bar extrusion, pipe extrusion, solid aluminum extrusion, hollow aluminum extrusion, variable section aluminum extrusion, single product extrusion (single hole die extrusion), multi- Product extrusion (porous die extrusion).

7, according to the type of equipment: vertical extrusion, horizontal extrusion, continuous extrusion.

Aluminum profile processing and extrusion

1. According to the extrusion direction: it can be divided into forward extrusion, reverse extrusion and lateral extrusion.

Second, according to the deformation characteristics: plane deformation extrusion, axisymmetric deformation extrusion, general three-dimensional deformation extrusion.

3. According to the lubrication state: non-lubricated extrusion, lubricated extrusion, glass lubrication extrusion, ideal lubrication extrusion (hydrostatic extrusion).

Fourth, according to the extrusion temperature: cold extrusion, warm extrusion, hot extrusion.

5. According to the type of mold or mold structure: flat die extrusion, cone die extrusion, split die extrusion, and perforated needle extrusion.

6. According to the shape or number of blanks: bar extrusion, pipe extrusion, solid aluminum extrusion, hollow aluminum extrusion, variable section aluminum extrusion, single product extrusion (single hole die extrusion), multi- Product extrusion (porous die extrusion).

7, according to the type of equipment: vertical extrusion, horizontal extrusion, continuous extrusion.

Leave a comment