Application of industrial aluminum profiles in the field of assembly lines

As long as there are industrial production sites, you can see the appearance of industrial aluminum profiles, such as automobile assembly plants, home power plants, robotics, automation, food production plants, chemical raw material production lines, etc. These places require the use of plumbing equipment. The application of industrial aluminum profiles in the field of assembly lines is also very important.

The assembly line is also called the assembly line. The frame is composed of industrial aluminum profiles. And according to different functions are divided into different types. Commonly used are belt line, chain plate line and drum line, which is an industrial production mode that combines man and machine. It can be transported according to a specified schedule and perform a variety of different tasks at the same time. The throughput is considerable and much more efficient than manual production.

The most common is the assembly line equipment of the electronics factory, usually the belt line. Because electronics factory products are usually smaller and more delicate, mounting the belt line on an industrial aluminum frame can take its weight. Some of the assembly lines are also equipped with aluminum workbenches for placing tools and materials. There are also workbenches that need anti-static, which are made of industrial aluminum profiles, which can play the role of anti-static and ensure the safety of production.

Corresponding material turnover vehicles should be equipped next to the assembly line. Each assembly line produces different things and deploys different materials. Putting material on aluminum rotors ahead of time is a very necessary step to increase production efficiency. The things produced cannot all be piled up on site, and must be placed individually in designated places. Because many semi-finished products require a certain amount of time before entering the next process, it is necessary to use industrial aluminum profile shelves to place them.

According to demand, industrial aluminum racks include ordinary warehouse racks and aluminum vanguard racks, which have a certain bearing capacity. You can use aluminum to deploy corresponding bolts, nuts, angles and other accessories. Install casters to move back and forth, easy to assemble, and can continue to be used after disassembly without any waste. , the products produced by the assembly line are placed on the aluminum rack to manufacture the products.

If it is an automobile manufacturing plant, many parts need to be completed by the assembly line during production. The production of automobiles is large and the efficiency of manual production is low, so the assembly line is necessary. Robots are used in welding factories and assembly factories. The outside of the welding robot should be protected by a protective cover made of industrial aluminum profiles. The protective film is generally composed of aluminum plus acrylic, aluminum or plexiglass plates to prevent sparks from splashing to human eyes. The assembly robot is surrounded by an industrial aluminum safety fence, which generally consists of a net, which is also used to demarcate the safety zone. Assembly lines are also used in the assembly workshop to assemble parts and casings, save space, use elevators, and surround them with industrial aluminum safety fences to prevent casings or parts from being scattered and hurting workers.

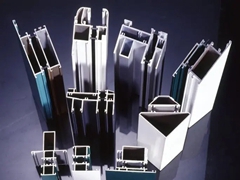

Industrial aluminum profiles

The assembly line is also called the assembly line. The frame is composed of industrial aluminum profiles. And according to different functions are divided into different types. Commonly used are belt line, chain plate line and drum line, which is an industrial production mode that combines man and machine. It can be transported according to a specified schedule and perform a variety of different tasks at the same time. The throughput is considerable and much more efficient than manual production.

The most common is the assembly line equipment of the electronics factory, usually the belt line. Because electronics factory products are usually smaller and more delicate, mounting the belt line on an industrial aluminum frame can take its weight. Some of the assembly lines are also equipped with aluminum workbenches for placing tools and materials. There are also workbenches that need anti-static, which are made of industrial aluminum profiles, which can play the role of anti-static and ensure the safety of production.

Corresponding material turnover vehicles should be equipped next to the assembly line. Each assembly line produces different things and deploys different materials. Putting material on aluminum rotors ahead of time is a very necessary step to increase production efficiency. The things produced cannot all be piled up on site, and must be placed individually in designated places. Because many semi-finished products require a certain amount of time before entering the next process, it is necessary to use industrial aluminum profile shelves to place them.

According to demand, industrial aluminum racks include ordinary warehouse racks and aluminum vanguard racks, which have a certain bearing capacity. You can use aluminum to deploy corresponding bolts, nuts, angles and other accessories. Install casters to move back and forth, easy to assemble, and can continue to be used after disassembly without any waste. , the products produced by the assembly line are placed on the aluminum rack to manufacture the products.

If it is an automobile manufacturing plant, many parts need to be completed by the assembly line during production. The production of automobiles is large and the efficiency of manual production is low, so the assembly line is necessary. Robots are used in welding factories and assembly factories. The outside of the welding robot should be protected by a protective cover made of industrial aluminum profiles. The protective film is generally composed of aluminum plus acrylic, aluminum or plexiglass plates to prevent sparks from splashing to human eyes. The assembly robot is surrounded by an industrial aluminum safety fence, which generally consists of a net, which is also used to demarcate the safety zone. Assembly lines are also used in the assembly workshop to assemble parts and casings, save space, use elevators, and surround them with industrial aluminum safety fences to prevent casings or parts from being scattered and hurting workers.

Industrial aluminum profiles

Leave a comment